Pure Steam Quality Test

The testing involved in Facility Utility pure steam validation requires a continuous supply of saturated steam; preferably sourced from the actual line that supplies your sterilization systems. Too high a level of non-condensible gases will prevent the attainment of sterilization; too little moisture carried in suspension may allow the steam to become super-heated during expansion into the chamber, while excess moisture may cause damp loads. Where steam systems are either routinely or irregularly shut down, large quantities of air will be present in the distribution system on restarting. It is recommended that in such circumstances a comprehensive and validated venting procedure should be applied and testing steam quality should be routinely executed.

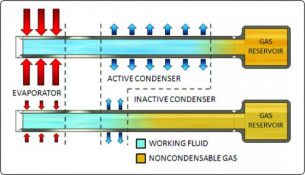

Non-condensible gases originate from the water

that the steam is generated from. These gases

will usually be air, although carbon dioxide

may be present, caused by certain water

treatment processes, typically water

softeners. This is exacerbated by excessive

aeration that can exist in many pharmaceutical

water treatment plants where water is

constantly recirculated and sprayed into the

top of storage vessels. The effect of such

gases being present in the steam supply to a

sterilizer can be the same as air, none

sterilization of the volume they occupy.

Non-condensible gases originate from the water

that the steam is generated from. These gases

will usually be air, although carbon dioxide

may be present, caused by certain water

treatment processes, typically water

softeners. This is exacerbated by excessive

aeration that can exist in many pharmaceutical

water treatment plants where water is

constantly recirculated and sprayed into the

top of storage vessels. The effect of such

gases being present in the steam supply to a

sterilizer can be the same as air, none

sterilization of the volume they occupy.

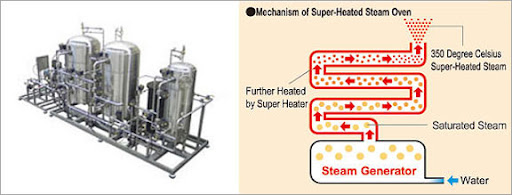

Superheated steam is steam at a temperature

above its boiling point for its pressure.

Superheated steam is a clear colour-less gas

that will not condense until its temperature

drops to its boiling point. Until this occurs

the moisture necessary for sterilization

cannot be produced and therefore presents a

risk to the process. Superheated steam acts as

hot air and requires sustained high

temperatures and long hold times before

sterilization can occur. It is essential in

facility utility pure steam validation to

verify that the steam being tested is not

superheated.

Superheated steam is steam at a temperature

above its boiling point for its pressure.

Superheated steam is a clear colour-less gas

that will not condense until its temperature

drops to its boiling point. Until this occurs

the moisture necessary for sterilization

cannot be produced and therefore presents a

risk to the process. Superheated steam acts as

hot air and requires sustained high

temperatures and long hold times before

sterilization can occur. It is essential in

facility utility pure steam validation to

verify that the steam being tested is not

superheated.

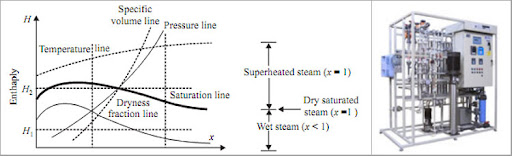

Wet steam is undesirable as it has less energy

than dry steam and more importantly can cause

wet loads. The packaging used for sterile

products prevents reinfection when dry, but

its bacterial retentive properties will be

adversely affected by the presence of

moisture. Wet loads can be considered to be

un-sterile. The dryness fraction describes how

dry steam is, with a value of 1 representing

steam that is 100% dry and therefore free of

entrained moisture. Steam with a dryness

fraction of 0.99 consists of 99% steam and 1%

water. If we measure the latent heat present

in steam that has a dryness fraction of 0.99

we will find that it possesses 99% of the full

quotient of latent heat.

Wet steam is undesirable as it has less energy

than dry steam and more importantly can cause

wet loads. The packaging used for sterile

products prevents reinfection when dry, but

its bacterial retentive properties will be

adversely affected by the presence of

moisture. Wet loads can be considered to be

un-sterile. The dryness fraction describes how

dry steam is, with a value of 1 representing

steam that is 100% dry and therefore free of

entrained moisture. Steam with a dryness

fraction of 0.99 consists of 99% steam and 1%

water. If we measure the latent heat present

in steam that has a dryness fraction of 0.99

we will find that it possesses 99% of the full

quotient of latent heat.